LABTWIN for Flexible Pipes

The LABTWIN project marks a milestone in the structural integrity assessment of submarine pipelines, introducing an innovative methodology for monitoring the degradation of flexible pipes. Collaboration with leading manufacturers and operators interested in the topic has enabled the allocation of pipe samples, both full-scale and reduced scale, subjected to conditions similar to those found in the field, specifically in the challenging context of the Brazilian pre-salt.

Challenge and Solution

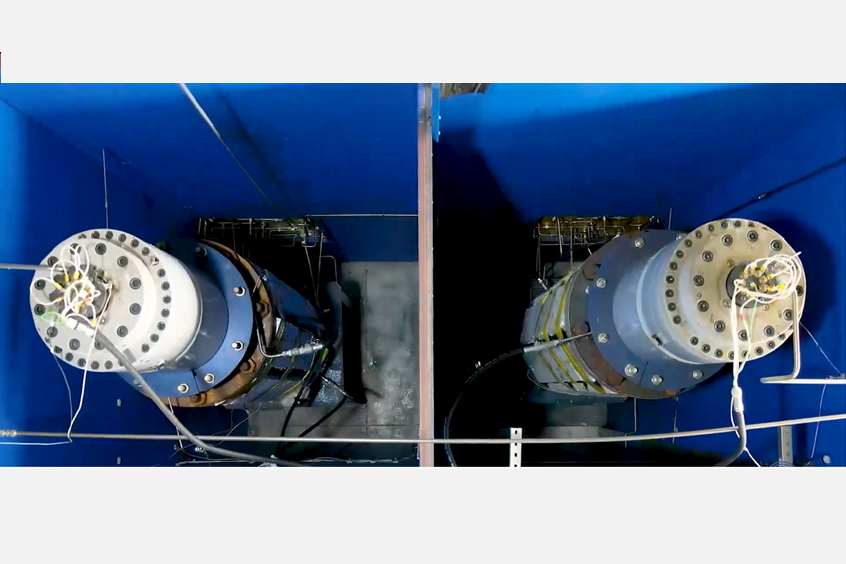

Given the complexity and high cost associated with conventional testing in hyperbaric chambers and in the field, LABTWIN emerged as an alternative that allows for controlled simulation of Subsea operational conditions in the laboratory. This approach not only simplifies and reduces the costs of integrity analysis of the pipes but also provides a safe method to predict the degradation of assets in operation.

Methodology and Development

The project developed and implemented a protocol of innovative methodologies to reliably reproduce the operational conditions of the pre-salt in a controlled laboratory environment. This protocol ranges from conceptual generation and material selection to the definition of manufacturing processes and the execution of experimental tests. The ability to generate data on the aging of pipes in the laboratory allows for an approximate prediction of the state of degradation of the pipes in operation, optimizing the effectiveness of risk mitigation actions, maintenance, and inspections.

Impact and Originality

The originality of LABTWIN lies in its ability to characterize and degrade flexible pipes in the laboratory under controlled conditions, providing a detailed view of their structural integrity. Collaboration with experts from Petrogal Brasil and Petrobras, as well as pipe manufacturers, enriched the project with a multidisciplinary approach, raising the level of knowledge about critical phenomena such as permeation and degradation by SCC-CO2.

Relevance and Applicability

LABTWIN has significant relevance to the sector, generating strategic knowledge about the degradation of flexible pipes in CO2-rich environments and supporting the development of more precise and reliable methods for designing and assessing structural integrity. Furthermore, the applicability of LABTWIN as an operational practice could transform asset management, offering a more economical, precise, and preventive monitoring technique in a controlled environment.

Benefits and Future Prospects

By adopting LABTWIN as an operational practice, the oil and gas sector can anticipate the behavior of flexible pipes in severe environments, optimizing maintenance and inspection plans and ensuring the integrity of assets both for planned service life and for operational life extension. This advancement promises not only economic benefits, by reducing operational costs and maximizing the lifespan of the pipes, but also environmental and safety benefits, minimizing the risk of failures and harmful impacts on the environment.