Fatigue and Fracture Mechanics Testing in Materials

Enhancing Safety and Efficiency through Strength and Toughness Testing

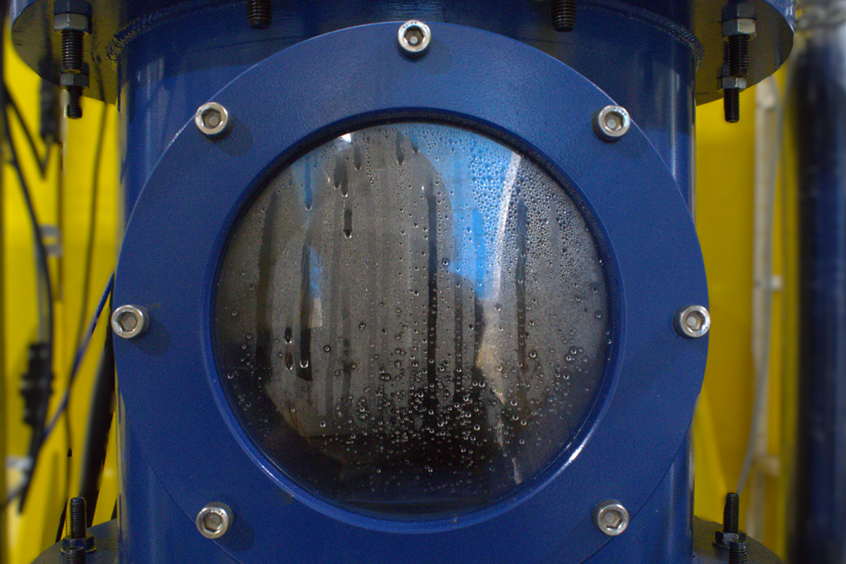

Fatigue and fracture mechanics tests on materials (e.g., da/dN-ΔK) are understood to be fundamental for evaluating the materials that make up the structural layers of flexible pipes. These tests enable the determination of the materials’ strength and toughness, generating critical data that help in predicting the service life and in anticipating necessary interventions to maintain the integrity of these assets.

Flexible pipes face severe challenges, from extreme pressures to adverse operating conditions. In response to these challenges, SIMEROS employs two evaluation approaches:

- Fatigue Testing on Structural Armor Wires: These tests assess the strength and durability of the wires that make up the structural layers of flexible pipes under submarine environmental conditions.

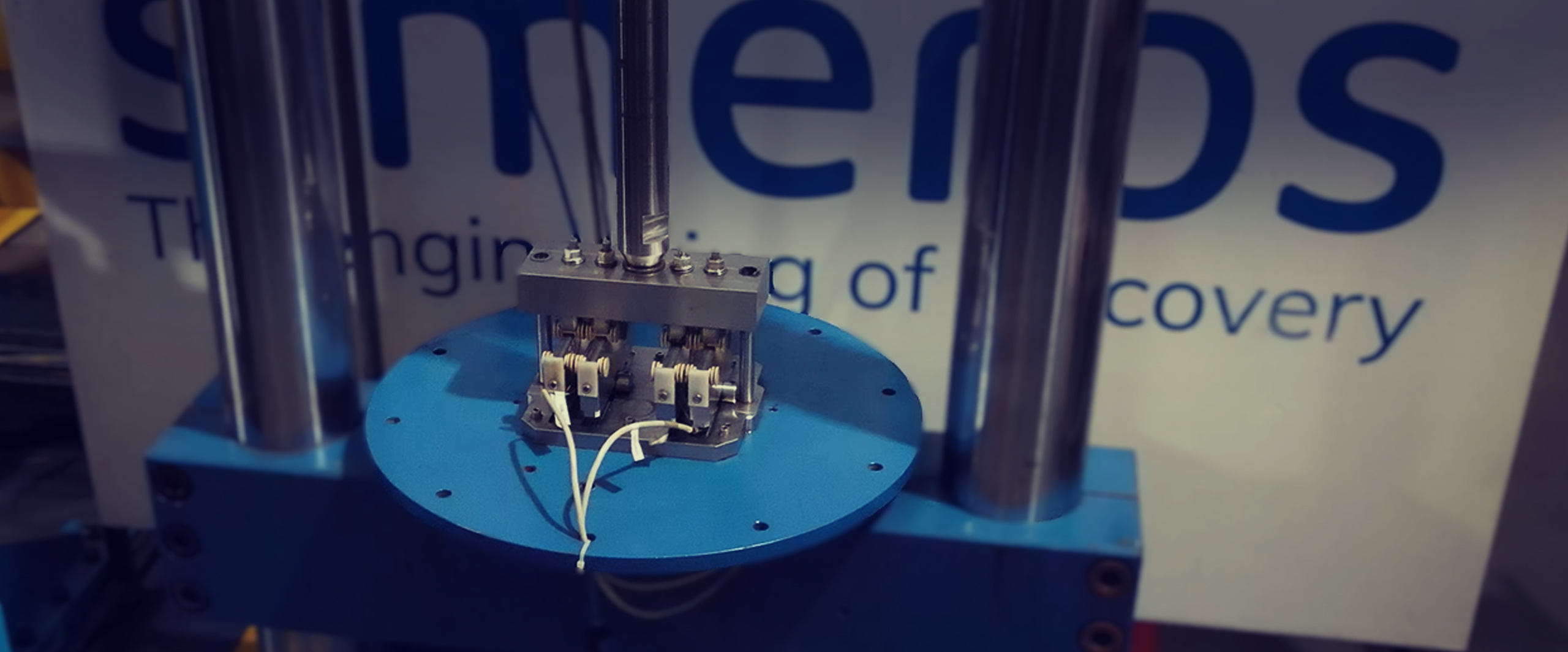

- Linear Elastic Fracture Mechanics Testing (da/dN-ΔK): These tests measure the fatigue crack growth rate, offering an understanding of how small cracks can evolve under various load conditions. This information is crucial for understanding the remaining service life of the pipes and proactively planning their maintenance or replacement.

Investing in the Future

These tests are not just technical procedures; they are essential strategic tools that:

- Expand the understanding of the structural integrity of flexible pipes, allowing for more effective management of their operational life.

- Provide valuable insights for developing robust maintenance and management strategies, minimizing risks and optimizing operability.

- Contribute to the sustainability of the O&G sector, enabling resources to be exploited safely and efficiently.

This approach reflects SIMEROS’s commitment to evaluating the integrity of flexible pipes, aiming to reinforce confidence in the operations of the O&G sector.