Experimental Evaluation of Thermoplastic Composite Pipes for Subsea Applications in The Oil & Gas Sector

Introduction to TCPs

Thermoplastic Composite Pipes (TCP) represent an evolution in pipeline technology for subsea applications in the Oil and Gas (O&G) sector. Comprised of alternating layers of thermoplastic materials and fiber reinforcements, they combine the mechanical strength of composites with the corrosion immunity of polymers. This combination results in lightweight and flexible pipes, offering substantial advantages over traditional metal pipes, especially in challenging subsea environments rich in CO2 and H2S.

Contributions of SIMEROS

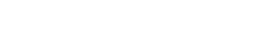

Since 2017, SIMEROS has been dedicated to the study of TCPs, developing and refining experimental test protocols specific to this technology. The company has also conducted qualification tests according to the DNV ST F-119 standard, in addition to meeting the stringent technical specifications required by O&G operators.

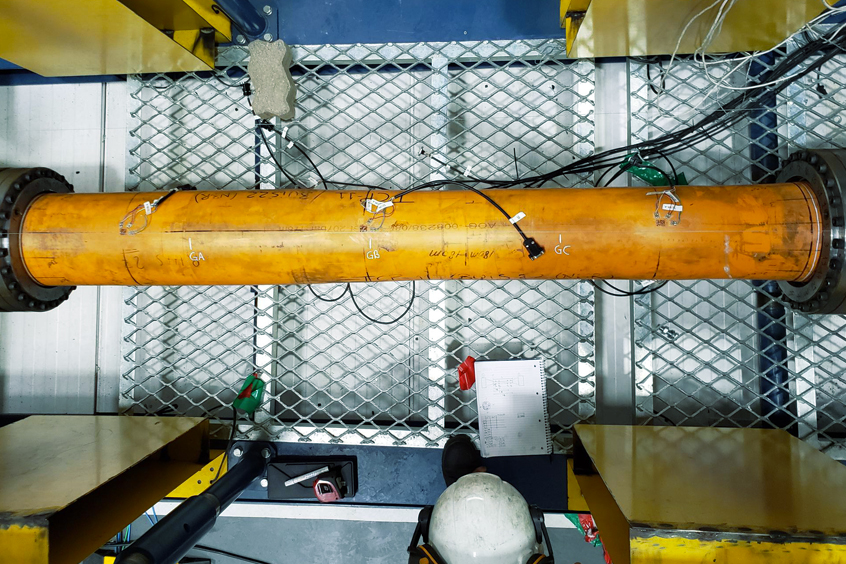

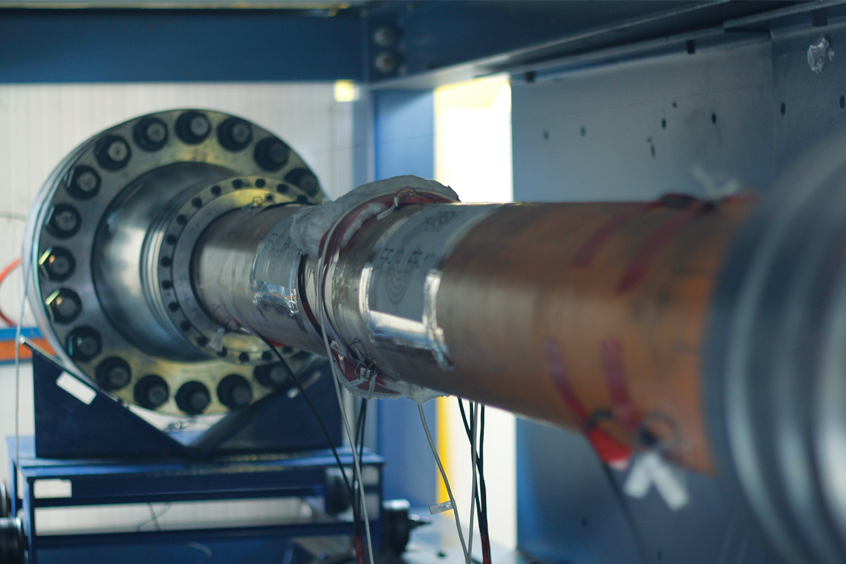

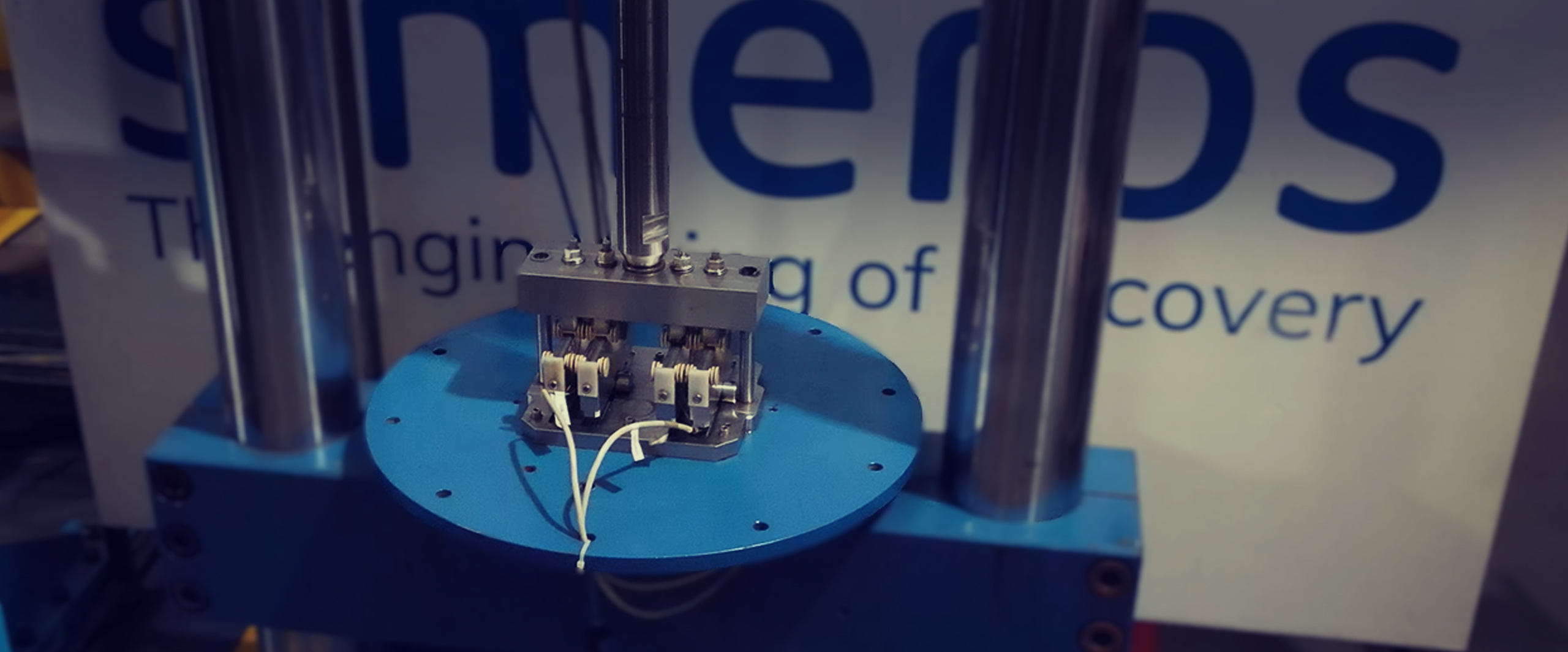

SIMEROS, in partnership with development collaborators, has invested in creating an advanced testing infrastructure capable of performing complex tests both at reduced and full scale. These tests simulate extreme operational conditions, including:

- High Pressures: Tests conducted under pressures that replicate those found in deep subsea environments.

- Thermal Amplitude: Temperature control ranging from -20 to +130°C, to ensure the resilience of materials under different operational conditions.

- Exposure to Production Fluids: Simulation of pipe contact with corrosive fluids common in O&G production.

- Static and Dynamic Loads: Evaluation of the pipes’ resistance to static and dynamic forces, applied individually and combined, experienced during movement, installation, operation, and decommissioning.

Impact and Relevance

The tests conducted by SIMEROS provide crucial data for understanding the behavior of TCPs under operational-like conditions, essential for risk mitigation, performance optimization, and extending the lifespan of these flow systems.